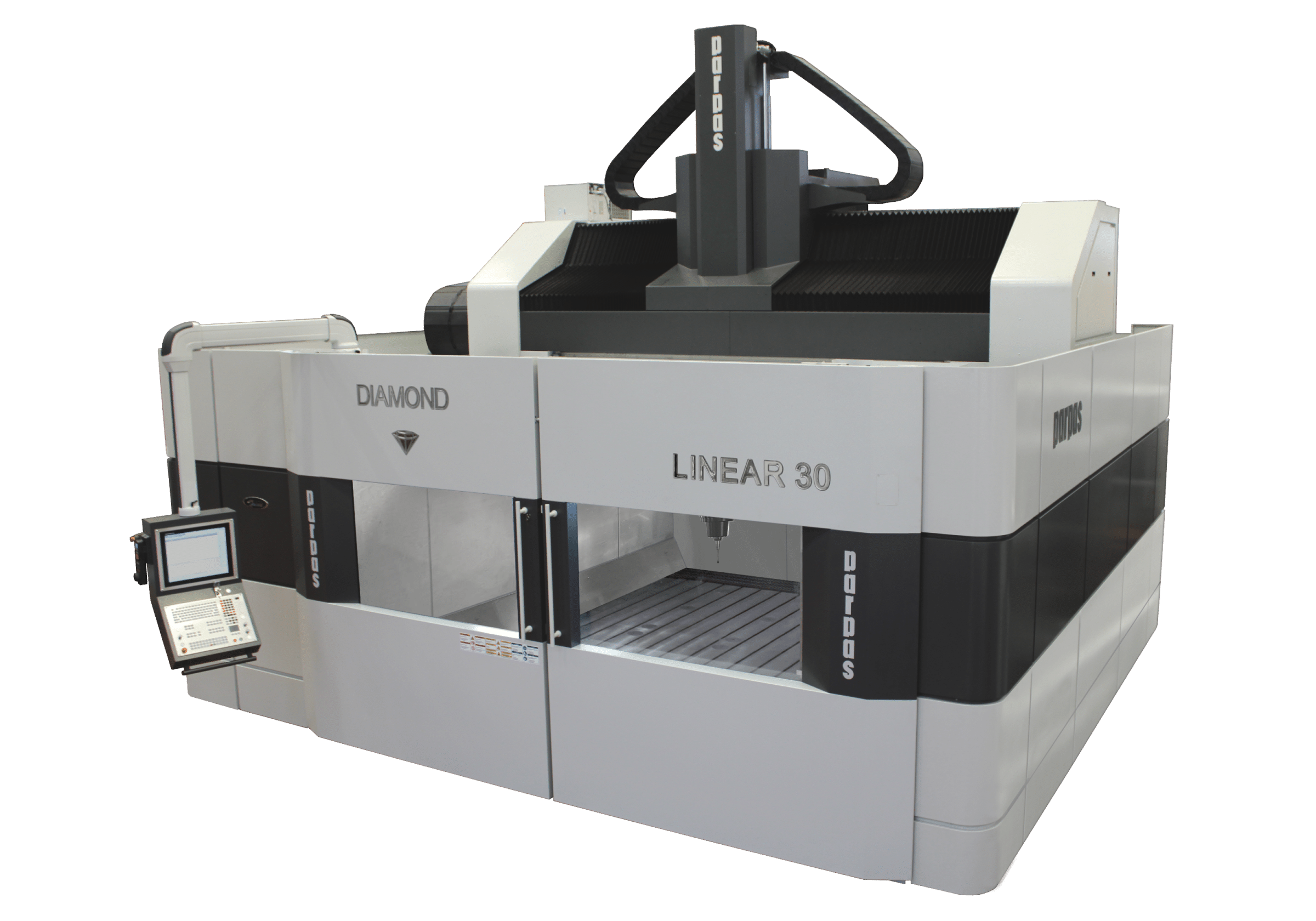

A new 5-axis gantry machine at DMM

DMM is modernizing its machine fleet with the acquisition of a PARPAS Diamond 5-axis gantry machining center. This state-of-the-art equipment allows us to support you even better in the design and manufacturing of your large-scale metal molds or for high-precision general mechanical work.

A cutting-edge machine for the manufacturing of metal molds

Our new PARPAS Diamond linear 30 , gantry machining center can machine large blocks. Thanks to its electro-spindle milling head, operating at 20,000 rpm, it is capable of performing high-precision machining in continuous 5-axis on 5 different faces without the need to disassemble the piece.

The PARPAS brand, present in our workshops for over 35 years, is an undeniable asset for the efficient management of preventive maintenance. Additionally, the Heidenheim interface, integrated into our entire machine fleet and mastered by our team, provides real flexibility and generates significant productivity gains.

Regular investments allow us to stay at the forefront of technology to best meet your needs.

This 5-axis gantry machining center now replaces 2 older machines in our workshop and provides better manufacturing quality while consuming less energy.

Reshoring the manufacturing of metal molds

The purchase of this 5-axis equipment was made possible thanks to support from the Auvergne Rhône-Alpes region under the “Reshoring Pack.” This initiative helps businesses involved in the reshoring of industrial activities to the region.

For over 30 years, DMM has been producing 100% French-designed and manufactured metallic molds in our workshop in Groissiat, Ain. To sustain this quality-focused strategy while remaining competitive in the market, it is essential for DMM to continuously modernize.

The arrival of our new 5-axis machine fully aligns with this approach. This new investment now offers customers the opportunity to reshore the production of their molds, which are currently manufactured in large quantities in Asia, to the Ain region.

At DMM, we fully understand the challenges of reshoring for plastics manufacturers. As a French mold maker, we are constantly seeking solutions to be more innovative and competitive. The addition of this 360° machine allows us to support this process by offering you top-quality service in the heart of the Plastics Valley.